Technical sheet

Description

Industrial Ethernet Cat.5e Torsion 4x2xAWG26-100 FR-PUR GN c(UR)us AWM

Application

for torsional stress, e.g. robotics using standard cable design

Conductor

Extra fine stranded bare copper wires AWG26

(data pairs) or AWG22 (power supply cores)

Insulation

Data pairs: (Foam-skin) polyolefin or fluorinated ethylene propylene (FEP)

Power supply cores: Polyolefin

Core identification

Data pairs: colour coded according to IEC 60708, DRIvE CLiQ-cables: green, yellow, pink and blue

Power supply cores: red and black

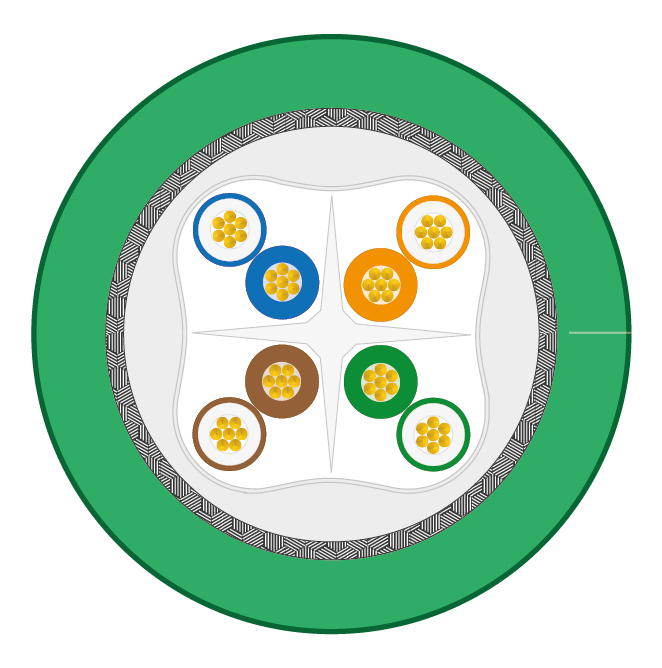

1° shield/armouring

Plastic bonded aluminium tape

Inner jacket/tape

Plastic tape

2° shield/armouring

Braid of tinned copper wires

Jacket colour

Green similar to RAL 6018

Operating temperature

-40°C to +80°C fixed installation

-25°C to +80°C fixed installation (FRNC)

-50°C to +180°C (short time use 205°C) fixed installation (FEP)

-10°C to +70°C flexible application

-30°C to +70°C flexible application (PUR)

Operating voltage

max. 125 v (peak value, not for connection to public mains)

Impedance

nom. 100 ohm according to IEC 61156-5 (solid conductor)

or IEC 61156-6 (stranded conductor)

Resistance

max. 187.6 ohm / km (AWG24, solid conductor)

max. 175.2 ohm / km (AWG24, 7-stranded conductor)

max. 280.0 ohm / km (AWG26)

max. 110.8 ohm / km (AWG22, power supply)

Nominal capacity

nom 48 nF/km

Bending Radius

8 x cable diameter fixed installation

15 x cable diameter flexible application

Approvals / norms

c(UL)us listing CMX according to UL 444

Oil resistance: IEC 60811-2-1

Flame resistance: IEC 6332-1-2, VW-1 (UL 2556)