Technical sheet

Description

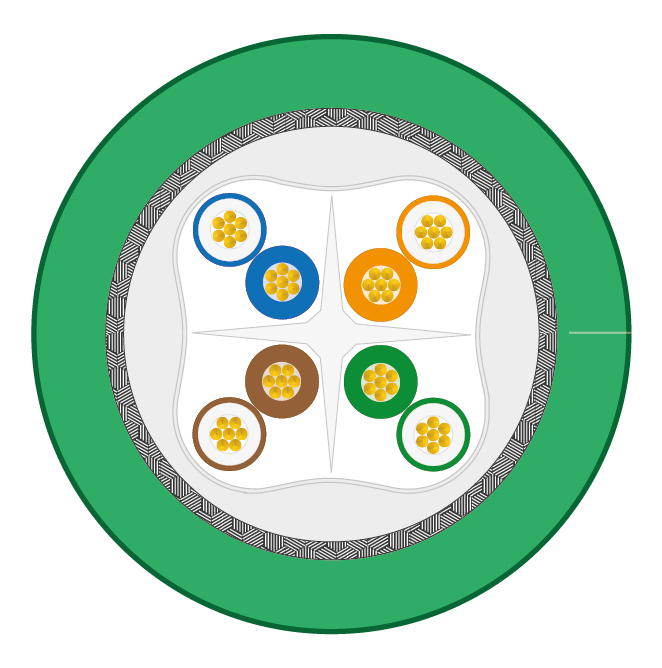

Industrial Ethernet Cat.5e highflex 2x2xAWG26-100 FR-PUR BU

Application

for continuous flexing, e.g. in drag chains, halogen-free

Conductor

Extra fine stranded bare copper wires AWG26

(data pairs) or AWG22 (power supply cores)

Insulation

Data pairs: (Foam-skin) polyolefin or fluorinated ethylene propylene (FEP)

Power supply cores: Polyolefin

Core identification

Data pairs: colour coded according to IEC 60708, DRIvE CLiQ-cables: green, yellow, pink and blue

Power supply cores: red and black

1° shield/armouring

Plastic bonded aluminium tape

Inner jacket/tape

Plastic tape

2° shield/armouring

Braid of tinned copper wires

Jacket colour

Green similar to RAL 6018

Operating temperature

-40°C to +80°C fixed installation

-25°C to +80°C fixed installation (FRNC)

-50°C to +180°C (short time use 205°C) fixed installation (FEP)

-10°C to +70°C flexible application

-30°C to +70°C flexible application (PUR)

Operating voltage

max. 125 v (peak value, not for connection to public mains)

Impedance

nom. 100 ohm according to IEC 61156-5 (solid conductor)

or IEC 61156-6 (stranded conductor)

Resistance

max. 187.6 ohm / km (AWG24, solid conductor)

max. 175.2 ohm / km (AWG24, 7-stranded conductor)

max. 280.0 ohm / km (AWG26)

max. 110.8 ohm / km (AWG22, power supply)

Nominal capacity

nom 48 nF/km

Bending Radius

8 x cable diameter fixed installation

15 x cable diameter flexible application

Approvals / norms

c(UL)us listing CMG according to UL 444, (UL) listing CL3 according to UL 13

Oil resistance: UL 2556

Flame resistance: IEC 6332-3-24, FT4 (UL 1685/CSA)

UV resistance: UL 2556